Examples of use

Spike system |

Technological procedure for mounting |

Characteristics of the system |

1.LEDGES AND WINDOW SILLS

2.EAVES GUTTERS AND SHARP EDGES

3.BEAMS, CYLINDRICAL SURFACES, AND RIDGE TILES

4.OVERHANGING SURFACES AND WINDOW SILLS

5.SURFACE UNEVENNESS

LEDGES AND WINDOW SILLS

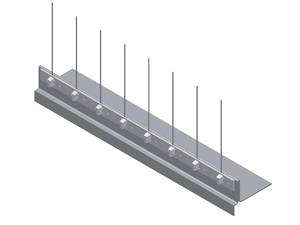

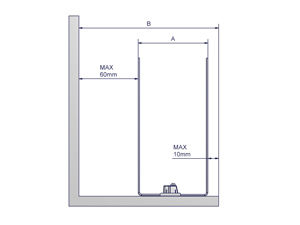

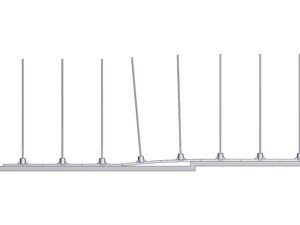

Systems with spikes vertical to the surface Varieties based on the width of the surface: H111, H111D, H114, H118 The treatment of ledges and window sills from 10 mm to 100 mm.

↑ Up

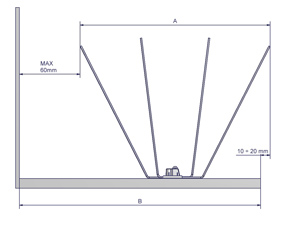

Systems with skew spikes Varieties based on the width of the surface: H112, H113, H123, H126, H127, H133 The treatment of ledges and window sills from 100 mm to 300 mm.

↑ Up

Double-row mounting on surfaces Varieties based on the width of the surface: 2x H123,2x H126, 2x H127, 2x H133 The treatment of ledges and window sills of a width exceeding 300 mm.

↑ UpEAVES GUTTERS AND SHARP EDGES

Eaves gutters H112 The treatment of a heavily used eaves gutter. The H112 system protects the bird landing edge and the area of the gutter.

↑ Up

Eaves gutters H111 The treatment of a lightly used eaves gutter. Enables easier access for cleaning.

↑ UpBEAMS, CYLINDRICAL SURFACES, AND RIDGE TILES

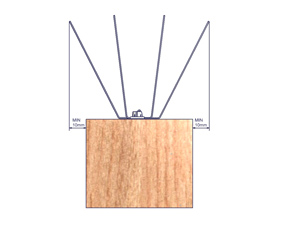

Beams H113, H123, H126, H127, H133 The treatment of beams, trusses, or wall plates requires spikes overlapping both bird landing edges.

↑ Up

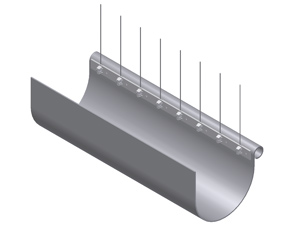

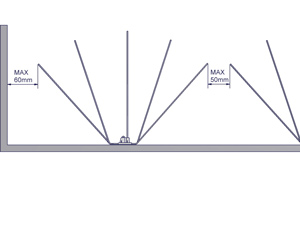

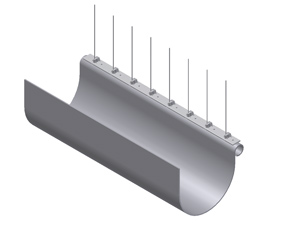

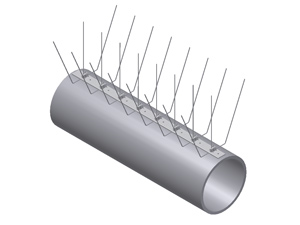

Cylindrical surfaces A variety based on diameter: H113, H123, H126 Very narrow bead of cylindrical surfaces, eaves conductors, or air-conditioning pipes.

↑ Up

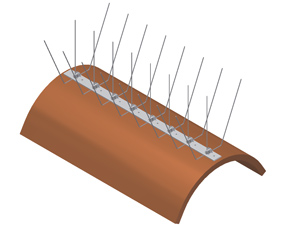

Ridge tiles Varieties based on the sharpness of the angle and the width of the ridge: H113, H123, H126 The treatment of roof ridges.

↑ Up

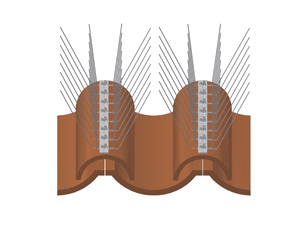

Roofs made of two-piece tiles Varieties based on span: H113, H123, H126, H127 The treatment of the edges of roofs made of two-piece tiles.

↑ UpOVERHANGING SURFACES AND WINDOW SILLS

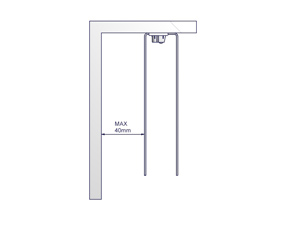

Overhanging surfaces H118 The treatment of overhanging surfaces to prevent the nesting of house martins.

↑ UpSURFACE UNEVENNESS

Minor unevenness The basic strip can adapt to minor surface unevenness. In the case of major unevenness, each strip can be easily shortened by breaking a piece off, and the mounting of the spike system can continue after the obstacle.

↑ Up

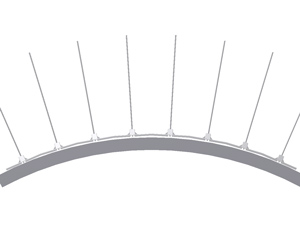

Convex surfaces Thanks to its flexibility and shape memory, the basic strip can be bent in a way that it enables it to be mounted on convex surfaces. The bending is carried out using scored lines between the individual segments of the basic strip. The level of bending is determined by the radius of the convex surface.

↑ Up

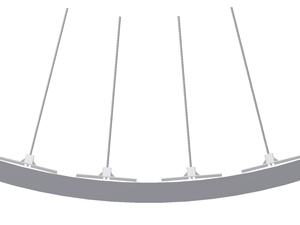

Concave surfaces For the treatment of concave surfaces, it is necessary to break the strip into individual segments and place those in a way that the spacing between the tops of the spikes is 30 mm to 40 mm. The breaking is carried out using scored lines between the individual segments of the basic strip.

↑ Up